- Home

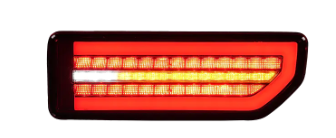

- Products

- Tail Lamp for TOYOTA Series

- Tail Lamp for HONDA Series

- Tail Lamp for TESLA Series

- Tail Lamp for CHEVROLET Series

- Tail Lamp for BUICK Series

- Tail Lamp for MAZDA Series

- Tail Lamp for VOLKSWAGEN Series

- Tail Lamp for NISSAN Series

- Tail Lamp for SUZUKI Series

- Tail Lamp for FORD Series

- Tail Lamp for HYUNDAI Series

- Tail Lamp for RENAULT Series

- About Us

- News

- Contact

English

English русский

русский Español

Español